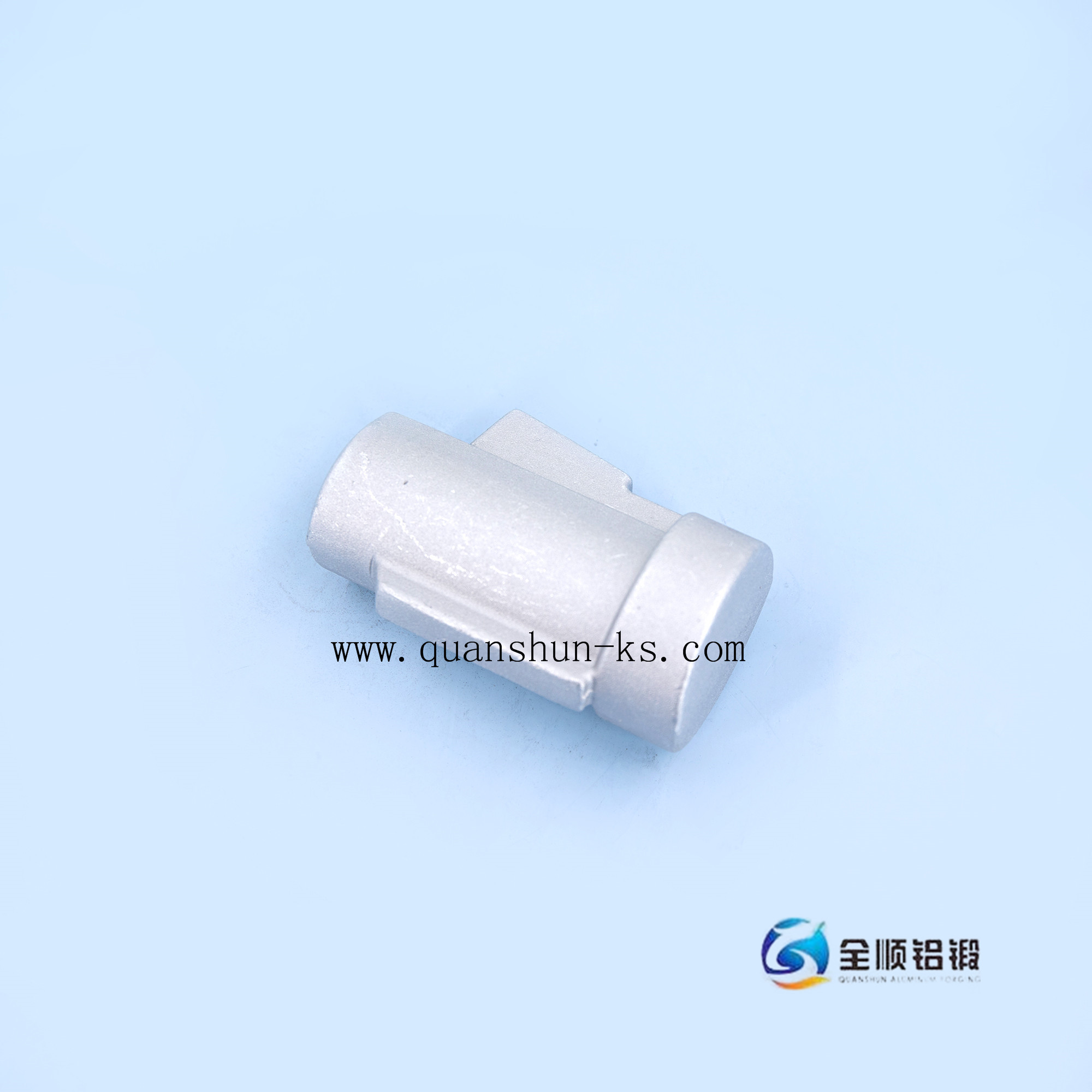

Introduction to aluminum forging process

Time:2020-09-27 Source:未知 Click:time

Aluminum forging temperature range is narrow

The deformation resistance of aluminum alloy increases with the decrease of temperature. The increase rate is faster than that of carbon steel and low alloy steel. In addition, when the die forging shop is too high or too low, aluminum alloy forgings are easy to produce defects. Therefore, the forging temperature range of aluminum alloy is narrow, especially the aluminum alloy with high degree of alloying can not be forged at high or low temperature.

Two, the heating temperature precise measurement

Because the forging temperature range of aluminum alloy is very narrow, and heated to about 400 degrees, the color of aluminum alloy unchanged; The naked eye cannot tell the temperature. Therefore, the temperature of aluminum alloy heating needs to be controlled by thermometer. And it must be unerringly controlled. Therefore, it is very important to measure the furnace temperature and billet temperature accurately. Radiant sensors (infrared) are increasingly used to measure the surface temperature of a blank.

Iii. Good thermal conductivity, but long heat preservation time.

Due to the complex phase composition of aluminum alloy, in order to ensure the full dissolution of the strengthened phase, its heating and holding time is longer than that of ordinary carbon steel, and the higher the alloying degree is. The longer you hold the heat. Reasonable heating and holding time, good plasticity of aluminum alloy, and can improve the forging performance of aluminum alloy. The insulation time is longer than that of carbon steel

Iv. Heating without oxide coating

Aluminum alloy does not produce loose scale when heated, but the product produces oxide film.

Small cold shrinkage (than steel).

The cold shrinkage rate of aluminum alloy is lower than that of steel, generally 0.06-1.0% (steel generally takes 1%-1.5%).

The forging process characteristics of aluminum alloy require corresponding measures to be taken in forging process and die design. Although the malleability of aluminum alloy is worse than that of carbon steel and low alloy structural steel, as long as the forging temperature of aluminum alloy blank is reasonable, the die roughness is low, the lubrication is good and the die preheating is good, etc. Conditions are optimized, the malleability of deformed aluminum alloy can be greatly improved, and the precision die forgings with complex shapes can be produced by die forging.

Online customer service

Online customer service