Automotive aluminum alloy - lightweight automotive mainstrea

Time:2020-09-27 Source:未知 Click:time

Automobile lightweight aluminum alloy contributes to the improvement of fuel economy mainly through the lightweight of automobile. Theoretical analysis and experimental results show that lightweight is an effective way to improve fuel economy. In order to meet the requirements of vehicle lightweight, some new materials emerge and expand the application scope.

Automotive aluminium alloy application advantages

1. Lightweight vehicles can help improve the riding stability, comfort and safety performance of passengers.

2, aluminum alloy lightweight cars can also reduce carbon dioxide emissions, reduce air pollution, improve the environment.

3, aluminum alloy lightweight car weight reduction, but also has considerable energy saving effect, the general weight of the car to reduce 1 kilogram, 1L of fuel can make the car more 0.011 kilometers.

4, aluminum alloy lightweight can significantly reduce the weight of the car, at the same time, the earth's large reserves of aluminum, aluminum alloy recovery and recycling efficiency is high, low cost, little impact on the environment.

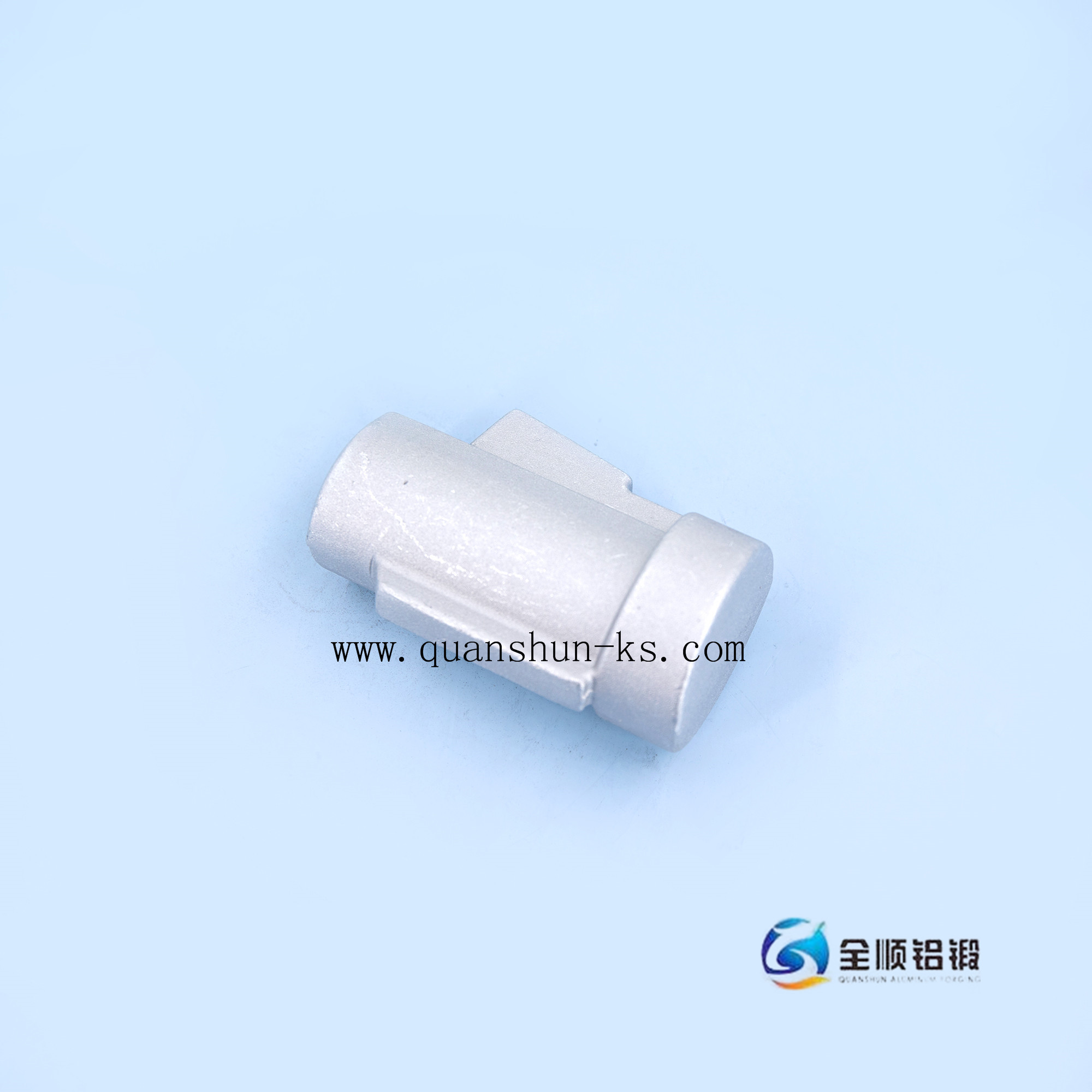

Automotive aluminium alloy

Types of automobile aluminum alloy

1. Casting aluminum alloy

Many kinds of elements can be used as alloying elements of casting aluminum alloy, but only Si, Cu, Mg, Mn, Zn, Li have important significance in mass production. Of course, it is not the simple binary alloy mentioned above that is widely used in automobiles, but the addition of many elements at the same time to obtain a good comprehensive performance.

The inevitable defects in aluminum castings and the fact that die castings cannot yet be heat-treated limit the use of aluminum alloys to produce castings of higher strength. For this reason, the casting process has been improved, and the casting forging and semi-solid forming process will be more used in the future.

2. Deformed aluminum alloy

Deformed aluminum alloy refers to aluminum alloy plate and strip, extruded profile and forged material, mainly used in automobile body panel, body frame, engine radiator, air conditioning condenser, evaporator, wheel, decorative parts and suspension system parts.

Aluminium radiators originated in Europe and then spread all over the world. In Europe, aluminum radiators accounted for 90 percent of the market by the late 1980s. With the extensive use of air conditioners and oil coolers, the market for aluminum heat exchangers is expanding rapidly. From the point of view of materials, the wide application of aluminum in heat exchangers is largely due to the successful development of coated aluminum plates and belts.

3. Aluminum matrix composites

Aluminum matrix composite has low density, high specific strength and modulus and good thermal fatigue resistance. However, its application in automobile is restricted by price and production quality control, and it has not yet formed a large scale. At present, the aluminum matrix composite material in the connecting rod, piston, cylinder body hole, brake disc, brake clamp and drive shaft tube and other parts of the test or use has shown excellent performance.

Please feel free to contact us for more information about aluminum alloy.

Online customer service

Online customer service